Cells are widely used for laptop batteries, digital home appliances(like vacuum cleaners), solar energy storage system(like municipal street lights and other outdoor lighting lamps), LED lighting, power tools(like mowers), low-speed EV( like two/three-wheeled electric vehicles), etc.

Therefore, here we will carry on the second part of the lithium ion cell production process introduction and machine equipment display.

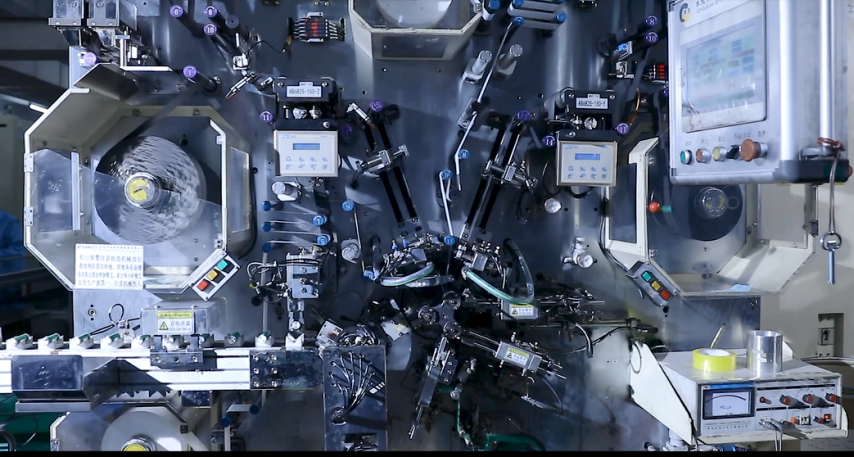

7. Winding: Usually the negative pole is long and the positive pole is short while winding.(Pay attention to winding speed and diaphragm tension.)

8. Into the shell: When the coil is put into the steel shell, pay attention to the positive and negative electrode directions, and place a gasket between the negative pole ear and the coil of the cell.(The gasket should not be missed or ectopic.)

9. Groove rolling: Before rolling groove, put a gasket on the positive pole; pay attention to the height above the groove and the total height.

10. Welding cap: Welding cap to positive electrode by laser.(Our digital cells have PTC and explosion-proof valve.)

11. Vacuum baking: Temperature is 85 ℃ and vacuum degree is(0.085 --- 0.1) MPa. Baking time: 4 hours.